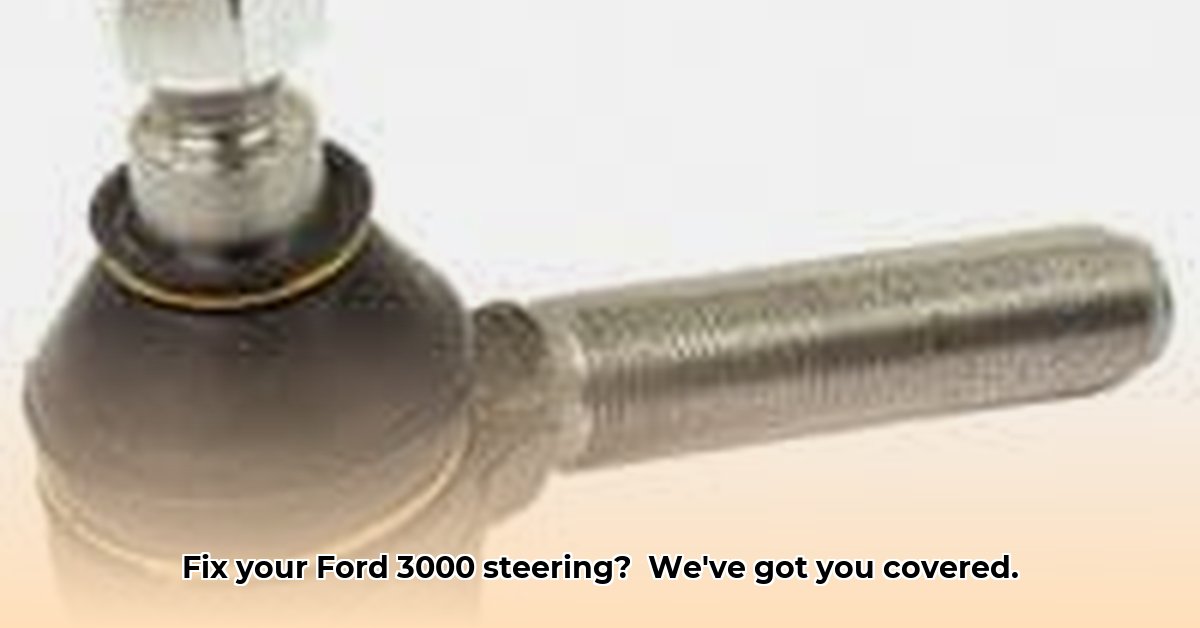

Steering problems on your 1965 Ford 3000 can make even simple tasks a struggle. A faulty steering ball joint is a common culprit, and sourcing replacement parts can be challenging. This comprehensive guide provides step-by-step instructions to diagnose, repair, or replace your tractor's steering ball joint. For electrical troubleshooting, check out this helpful wiring diagram.

Identifying a Faulty Steering Ball Joint

A worn steering ball joint manifests in several ways. Do you find steering unusually stiff, especially at low speeds? Are there disconcerting knocking or clunking sounds when turning the wheel? Excessive looseness or play in the steering also points towards a problem. Inspect the ball joint visually; cracks, damage, or significant wear necessitate replacement. Addressing this issue promptly prevents further damage and ensures safe operation of your tractor. Have you noticed any of these issues? It's time for a close inspection.

Tools and Materials: Gathering Your Arsenal

Before starting the repair, assemble the necessary tools and parts. The right tools ensure safety and efficiency. Here is a detailed list:

| Part | Description | OEM Part Number (May vary; check your manual) | Aftermarket Options | Source | Notes |

|---|---|---|---|---|---|

| Steering Ball Joint | Connects the steering arm to the knuckle. | (Check your tractor's manual) | Numerous; Check Compatibility | Tractor parts suppliers, online retailers | Ensure precise fit. Measure carefully if possible. |

| Grease | High-quality lithium-based grease | N/A | Widely available | Auto parts stores | Essential for lubrication and longevity of the ball joint |

| Cotter Pin | Secures the ball joint. | N/A | Widely available | Auto parts stores | Replace with a new one. |

| Castle Nut | Secures the ball joint. | N/A | Widely available | Auto parts stores | Verify correct size before purchase. |

| Wrenches & Sockets | Various sizes; consult your tractor's manual | N/A | Widely available | Auto parts stores | Precise sizes are crucial for proper torque and safe disassembly. |

| Ball Joint Separator | Tool for safely removing the old ball joint. | N/A | Widely available | Auto parts stores, tool suppliers | Essential for minimizing damage to surrounding components. |

| Jack Stands | To securely support the tractor during repair. | N/A | Widely available | Auto parts stores | Critical for safety. Never work under a vehicle without jack stands. |

| Penetrating Oil | To loosen rusted or seized fasteners. | N/A | Widely available | Auto parts stores | Helps significantly in loosening stubborn components. |

| Safety Glasses | Eye protection | N/A | Widely available | Auto parts stores | Always wear safety glasses when working on machinery. |

| Gloves | Hand protection | N/A | Widely available | Auto parts stores | Essential for protecting your hands from grease and potential injury. |

Finding OEM parts for a 1965 tractor can be difficult. Aftermarket options are available, but carefully check reviews and compatibility before purchasing. Specializing suppliers for vintage tractors might be more reliable sources for hard-to-find parts.

Step-by-Step Replacement Guide

This section provides a detailed, step-by-step guide to replacing the steering ball joint. Remember, safety is paramount; always support the tractor on jack stands before beginning any work.

Safety First: Securely raise the tractor with a suitable jack and place it on sturdy jack stands. Disconnect the negative battery terminal. This crucial step prevents accidental shorts and potential injury.

Wheel Removal: Remove the wheel to access the steering components. This step provides adequate space to work on the ball joint.

Cotter Pin and Castle Nut Removal: Locate the cotter pin and castle nut securing the ball joint. Carefully remove the cotter pin with a suitable punch or pliers, and then unscrew the castle nut. Penetrating oil may be necessary. This step requires care to avoid damage to the components.

Ball Joint Separation: Use the ball joint separator to carefully separate the ball joint from the steering knuckle. This often requires firm but controlled pressure. Take your time to avoid damaging surrounding components.

Installation of the New Ball Joint: Carefully install the new ball joint, ensuring correct alignment. Ensure the new ball joint is correctly seated and aligned within the knuckle.

Reassembly: Reinstall the castle nut and cotter pin. Tighten the nut to the manufacturer's specified torque (refer to your tractor's manual).

Lowering the Tractor: Carefully lower the tractor from the jack stands.

Testing the Steering: Test the steering. It should be smooth and responsive, free from knocking or excessive play.

Troubleshooting Common Issues

If you encounter difficulties separating the ball joint, apply more penetrating oil and let it soak for several hours. If the new joint doesn't fit, double-check that you ordered the correct part for your 1965 Ford 3000. Incorrect part selection is a common cause of installation problems.

Preventative Maintenance

Regular lubrication of all steering components is vital. Greasing the ball joint extends its lifespan and prevents premature wear. Regular visual inspection of the steering system helps to identify potential issues early, preventing costly repairs down the line.

This guide aims to help you resolve steering issues on your 1965 Ford 3000. Remember, if you are unsure about any step, consult a qualified mechanic. Prioritize safety at all times.